Rock Deformation Laboratory

Contact:

Web:

Infrastructure belongs to:

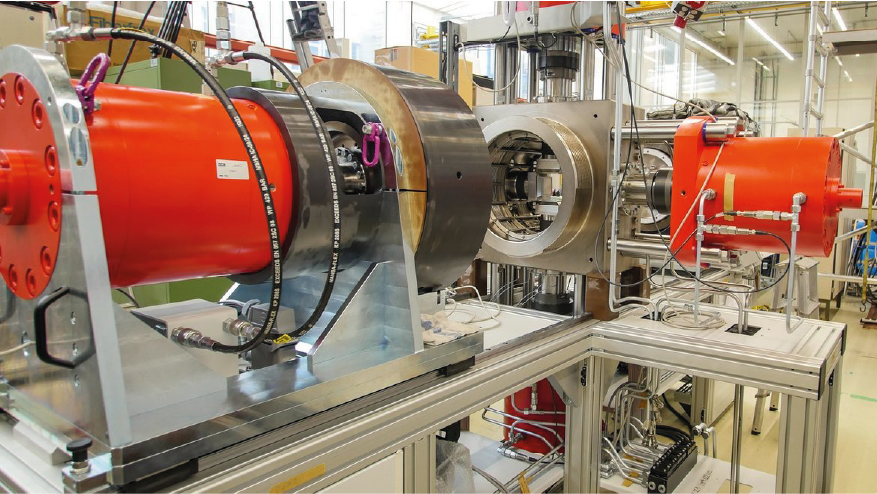

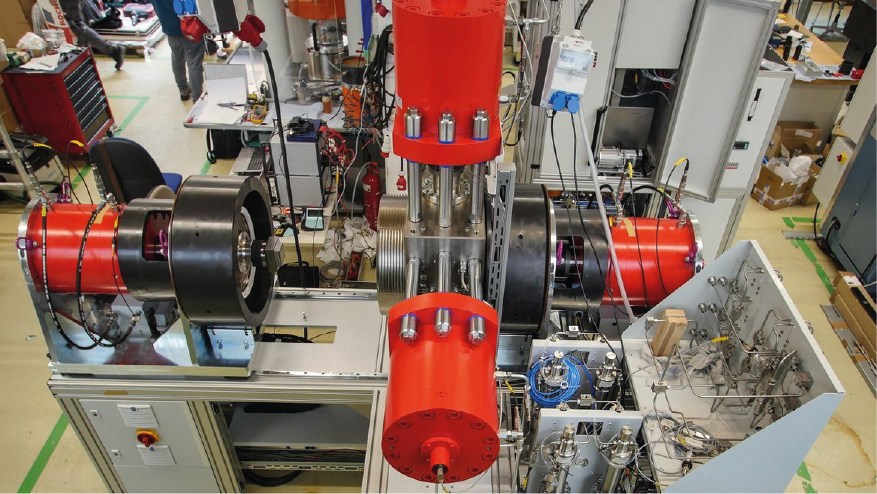

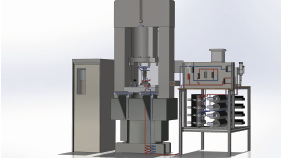

Polyaxial High-pressure Test System (TrueTriax)

The grant from the Investment Bank of the State of Brandenburg (ILB No. 85053766) enabled the acquisition of a high-pressure, high-temperature 3D True Triaxial Press facility at the GFZ, which is to be expanded beyond the scope of the project in a modular fashion and additionally utilised in a national cluster.

To this end, the core elements of a national high-pressure triaxial press cluster were set up and put into operation as part of this project. This includes a modularly expandable, cubic, polyaxial high-pressure testing facility for carrying out stress-strain analyses on rock samples under real triaxial pressure conditions with control options in all three main stress directions.

The facility is used to carry out highly specialised, experimental pressure tests on rocks, e.g. from boreholes. The experiments open up previously unattainable dimensions. The facility is coupled with a system for measuring acoustic emissions and a flow-through system. This makes the facility unique in Germany and even unique in the world. In addition, a surface grinder and a lathe will be purchased and put into operation for sample preparation and for setting up the experiments.

The uniqueness of the experimental facility results from the fact that a real true triaxial press operates in a high pressure and temperature range and is simultaneously coupled with

a) an acoustic emission (AE) system,

b) a flow-through system to quantify fluid-rock interaction, and

c) a hydraulic stimulation simulation module.

Mechanical Testing System (MTS)

With the mechanical testing system (MTS) hydrostatic pressures up to 140 MPa and temperatures up to 200 °C can be simulated. The pressure and temperature within the chamber are continuously monitored by an external pressure sensor and two internal thermocouples (Type K). Within the pressure chamber, the thermocouples are located at top and bottom of the test specimen. To measure the axial and lateral strains of the sandstone samples, two axial extensometers and one circumferential chain extensometer were installed during all tests. The hydraulic system Quizix C-6000-10 K is connected to the pore pressure ports. Quizix C-6000-10 K enables fluid volume measurements with a resolution of 0.0000135 ml up to maximum flow rates of 200 ml/min. The maximum possible pore pressure is 68.9 MPa with a static accuracy of 0.06%.

Easy to use ring Shear TEst Rig (ESTER)

Soil mechanical shear parameters such as maximum and residual shear strength are important for assessing the stability of buildings and other structures, but also of slopes. This also applies to submarine technical installations installed in shelf areas or on continental slopes. The ESTER ring shear cell was developed at the GFZ to investigate the influence of methane hydrates on the mechanical properties of sediments on the continental shelf. For this purpose, ESTER can be temperature-controlled and is equipped with a pore pressure system for pressures up to 20 MPa. The ring cell, with an outer diameter of 50 mm and an inner diameter of 30 mm, allows shear paths of any length to be applied to determine both the maximum shear strength and the residual shear strength when the shear joint is fully developed.

Categories

Disciplinary Keywords

Selected infrastructures

Instrumentation

Laboratory instrumentation

Instruments

-

Easy to use ring Shear TEst Rig (ESTER)

-

Mechanical Testing System

-

Triaxial Press